250TPH Stationary C&D Waste Processing Line in Jiangsu

Commissioning time : 2015

Location: Jiangsu, China

Material: Construction waste

Finished size: 0-5mm, 5-10mm, 10-15mm

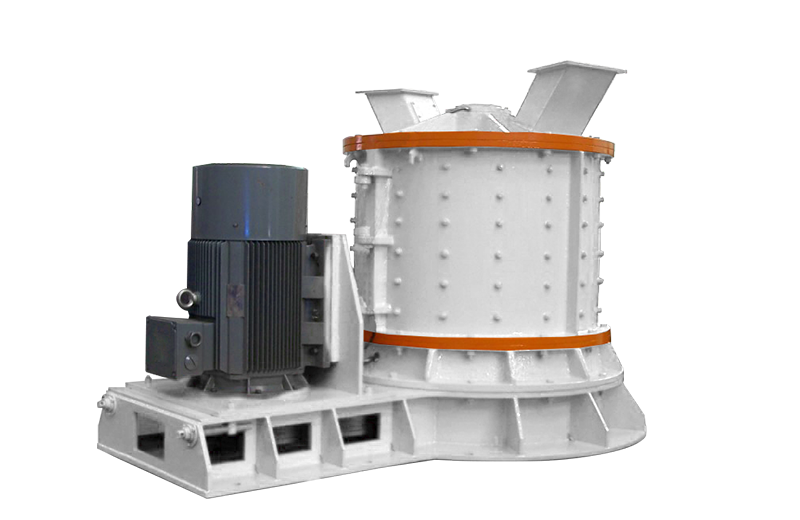

Nowadays policies encourage construction waste reduction, resource, harmless treatment, so a big enterprise in Jiangsu act on time, cooperate with Sandmine to build the construction waste dispoal project. Our engineers equipped a fixed production line with JCH European type jaw crusher, GIC impact crusher and VIC vertical shaft impact crusher as the core equipment, which is scientific, reasonable and efficient. The project not only made positive contribution to the local environmental protection, realized the recycling of waste, but also provides an example for other regions to follow.